Electrical maintenance activities

26 de noviembre de 2024

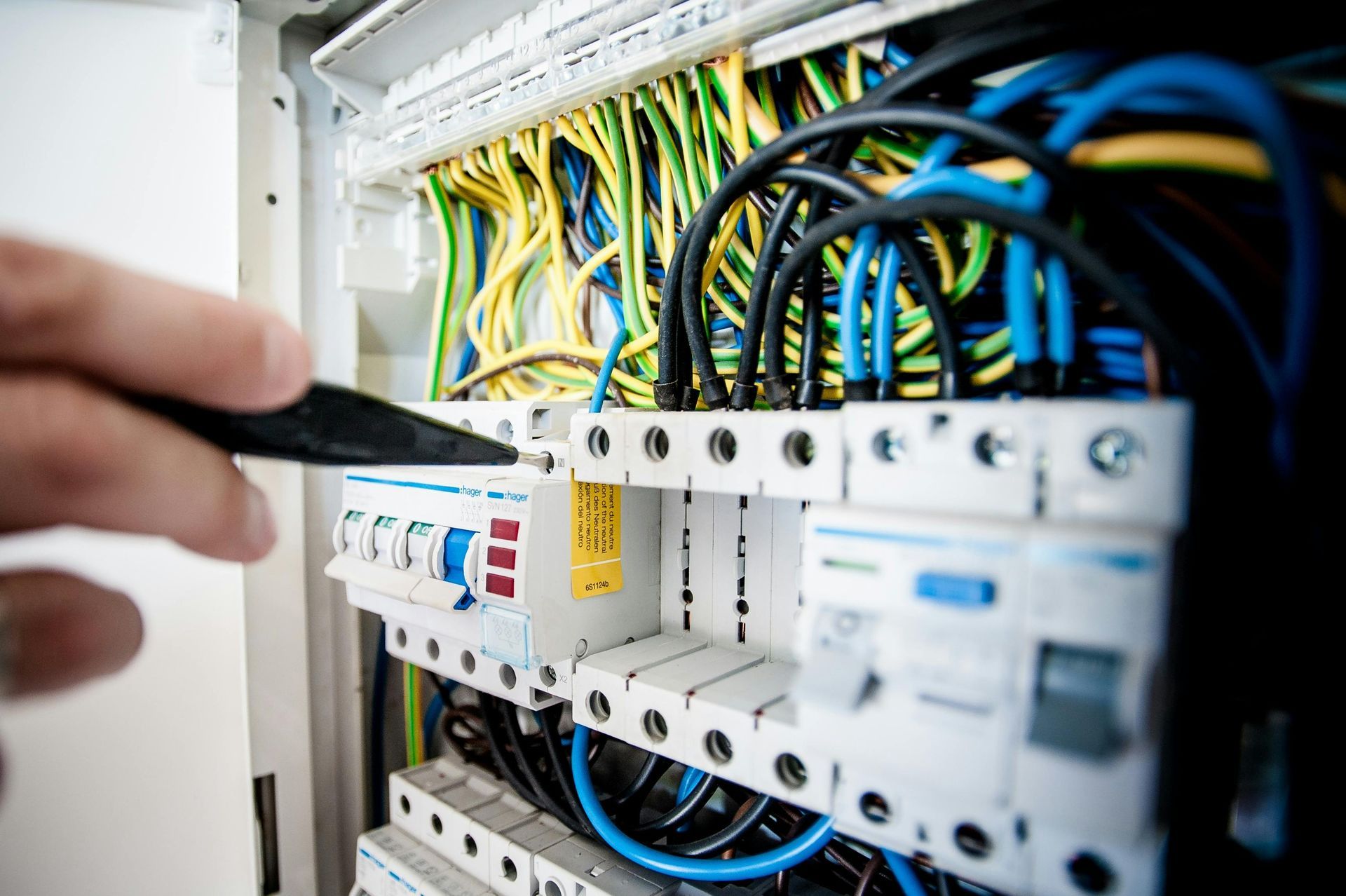

Electrical maintenance

Electrical maintenance is a crucial aspect of any facility, whether industrial, commercial, or residential. In a world increasingly reliant on electrical energy, ensuring that our electrical systems function correctly is not just a matter of efficiency but also of safety. This article aims to explore the various activities that comprise electrical maintenance, their functions and benefits, and how to implement them effectively.

Key Activities in Electrical Maintenance

Electrical maintenance includes several activities such as regular inspections, cleaning, and necessary adjustments to keep equipment in optimal condition. Some of the primary activities include:

- Corrective Maintenance: This involves repairing equipment that has failed. It may include tasks like replacing faulty components or troubleshooting issues to restore functionality.

- Predictive Maintenance: This relies on continuous monitoring of equipment conditions to anticipate imminent failures. Techniques used in predictive maintenance may include vibration analysis, thermal imaging, and other diagnostic tools.

Essential Functions of Electrical Maintenance

Electrical maintenance serves several essential functions:

- Ensuring Operational Continuity: Regular maintenance helps prevent unexpected breakdowns and production downtimes.

- Safety Assurance: Proper maintenance protects personnel from electrical hazards and reduces the risk of accidents.

- Asset Protection: By maintaining equipment, companies can extend the lifespan of their assets and reduce replacement costs.

Additionally, there are secondary functions that are equally important, such as improving energy efficiency and compliance with safety regulations.Implementing an effective electrical maintenance plan may seem like a monumental task; however, the benefits far outweigh the initial costs. A well-structured maintenance strategy not only enhances operational efficiency but also safeguards both people and material assets.

También te puede interesar